MOST FLEETS ARE LEAVING BIG MONEY ON THE ROAD. ARE YOU?

Get up to 30% more mileage out of your tires.

Discover Doctor Preload® Bearing Adjustment Tools and Temper-Loc® Spindle Nuts

Doctor Preload

Eliminate ALL endplay from wheel bearings.

Safely. Quickly. Consistently.

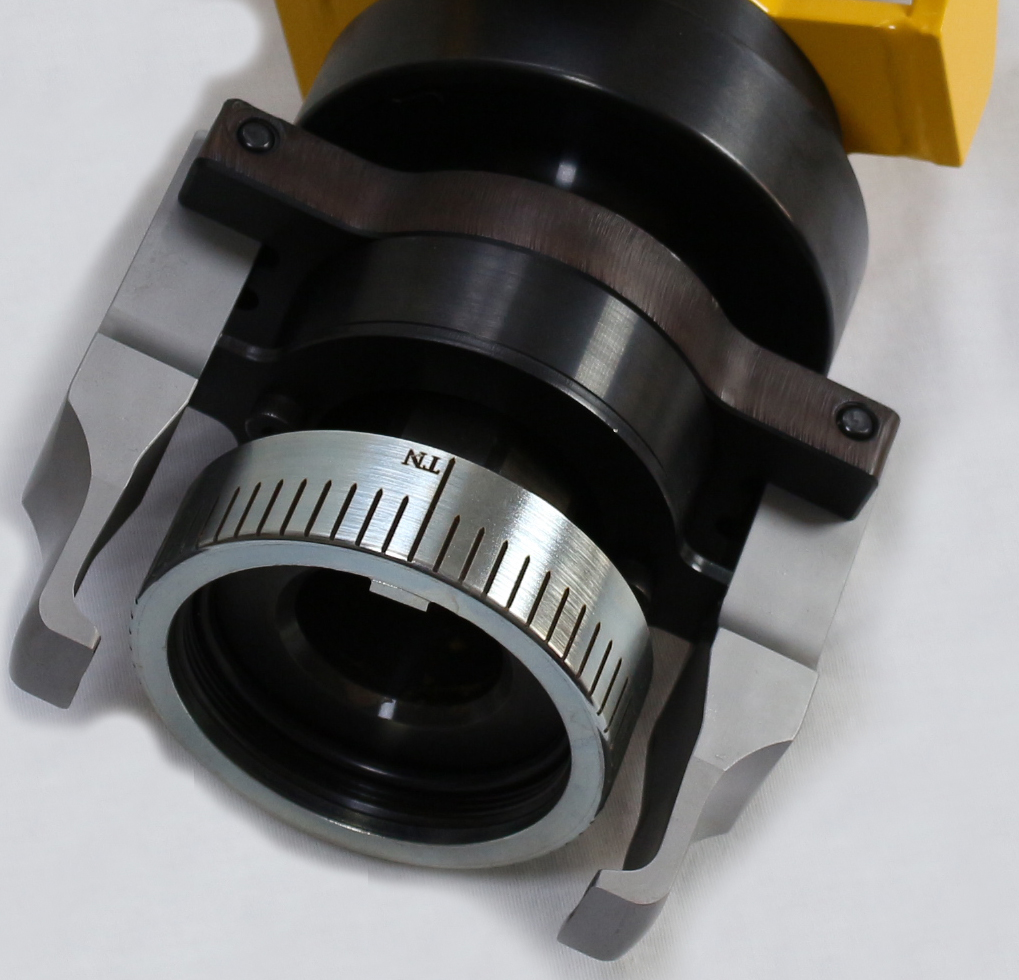

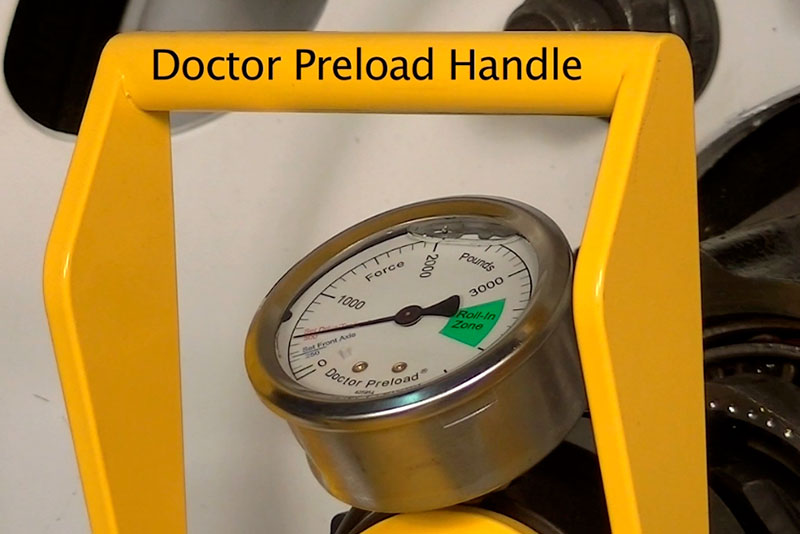

Doctor Preload bearing adjustment tools allow your technicians to quickly and accurately adjust wheel end bearings to SAE standard light preload settings while measuring preload forces all the way through the adjustment process and at the final preload setting.

SAE International, the technical and engineering leaders of the vehicle industry, published the specifications for light preload in heavy duty truck and bus wheel end bearings for optimal performance in March 2001. At that time there was no practical and safe way to adjust bearings to SAE specified preloads – until Temper Axle introduced Doctor Preload to the industry in 2009. Now there are no more excuses:

SAE International, the technical and engineering leaders of the vehicle industry, published the specifications for light preload in heavy duty truck and bus wheel end bearings for optimal performance in March 2001. At that time there was no practical and safe way to adjust bearings to SAE specified preloads – until Temper Axle introduced Doctor Preload to the industry in 2009. Now there are no more excuses:

- No reason to compromise wheel end and tire performance with outdated and cumbersome procedures.

- No reason for you to settle for poor performing wheel ends and tires.

- Absolutely no reason to leave that money on the road.

Fleets report achieving up to 30% increases in tire life due to more even tread wear. Wheel seal and bearing life and brake operation are also optimized with preload settings.

Ready to give it a try? Here’s how it works.

One Minute. Four Easy Steps.

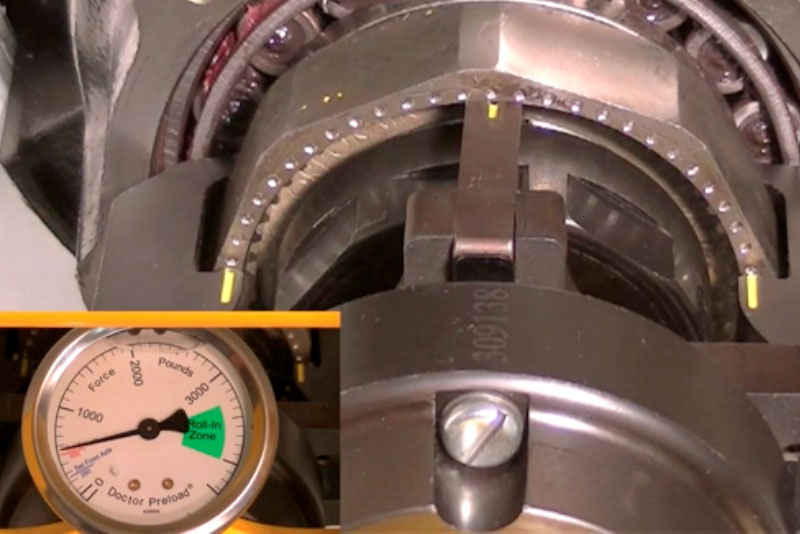

- Use Doctor Preload to apply a high force value directly to the bearings and “roll-in” the bearings to properly align the tapered rollers

- Use Doctor Preload to reduce the force to the exact light preload measurement specified by the experts at SAE International

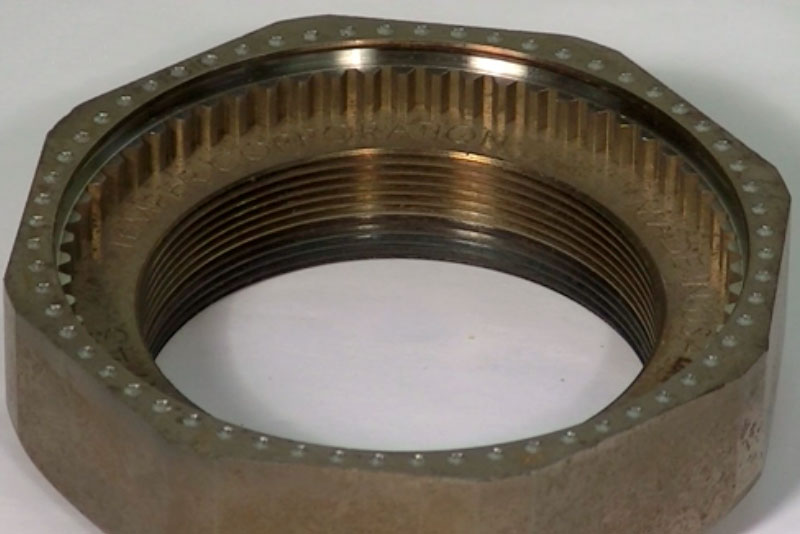

- Advance the Temper-Loc spindle nut to hold the optimal bearing setting in place

- Remove Doctor Preload from the spindle and install the positive locking retainer ring

Thorough inspection by the trained technician ensures a properly adjusted and secured wheel end bearing.

Over the past 10 years, fleets of all sizes have realized compelling benefits from this breakthrough technology, resulting in revolutionary wheel end performance levels.

Simple. Proven. Stable.

Doctor Preload also saves a lot of technician time.

Good Technicians are hard to recruit. Help them be more efficient.

Using Doctor Preload to adjust a wheel end bearing takes about one minute from start to finish. Together with Temper-Loc Spindle Nut, specially designed to work with Doctor Preload, the tool saves technicians hours of time by simplifying the steps involved in bearing adjustment and taking the guesswork out of consistently achieving preload settings. Fleets realize huge time and cost savings over other methods, which add up quickly.

Temper-Loc Spindle Nuts enable precise adjustment and come with a fingertip-control retainer ring technicians appreciate for its ease of use and safe operation. EasyView® tabs help technicians confirm spindle nuts are securely installed.

What is Preload?

Wheel end tapered roller bearings are designed to be set to preload. They are not designed to be “loose” or have endplay. In preload condition, all clearances (endplay) between components in the wheel end assembly are completely eliminated and the bearings are slightly compressed.

Keeping a light preload force on the bearings maintains roller alignment so they roll the way they should. The rest of the wheel end components including tires, seals, and brakes are all designed to work best under preloaded bearing settings.

Preload is not Pre-adjusted: “Pre-adjusted” is a term that refers to wheel ends with a cone spacer and higher cost “close tolerance bearings” that will set to endplay and reduce tire life. They cannot be adjusted to a better setting, without removal of the cone spacer.

Preload is not torque: Torque should never be used to adjust bearings to a presumed preload condition because the final preload setting cannot be measured, thus creating unsafe inconsistency in bearing settings.

Safety demands that preload always is set using direct measurement of the preload forces.

Is endplay hurting my fleet?

Yes: The more endplay, the more money you’ll spend on vehicle operation and maintenance. Bearings set to any amount of endplay, as small as a few thousandths of an inch, cause rapid and irregular tire wear, resulting in shorter tire and tread life. Developed by tire and chassis engineers, the Radial Tire Conditions Analysis Guide, Technology & Maintenance Council (TMC), Fourth Edition, identifies 14 different common irregular tire wear patterns that are caused by improper bearing adjustment. Setting to preload helps solve these problems. By removing endplay and setting bearings to preload, irregular wear is reduced or eliminated, enabling optimum tire performance and leaving less money on the road.

HERE’S WHAT THE EXPERTS SAY

Benefits

SAVINGS YOU CAN SEE

Our tools are proven to deliver significant advantages to fleets of all sizes – from a single owner operator to large national fleets. Doctor Preload and Temper-Loc spindle nuts used together offer significant benefits.

TRAINING

EFFICIENT AND CONSISTENT

Watch our videos and download our instructions and catalog sheets to see how easy it is to use our system to deliver pinpoint accuracy.

Complete Doctor Preload 900 Series Process

Doctor Preload 900 Series Training Part 1

Doctor Preload 900 Series Training Part 2

Doctor Preload 900 Series Tool for R Drive Axle

Complete Doctor Preload Process

Doctor Preload Components

Temper-Loc Nut Components

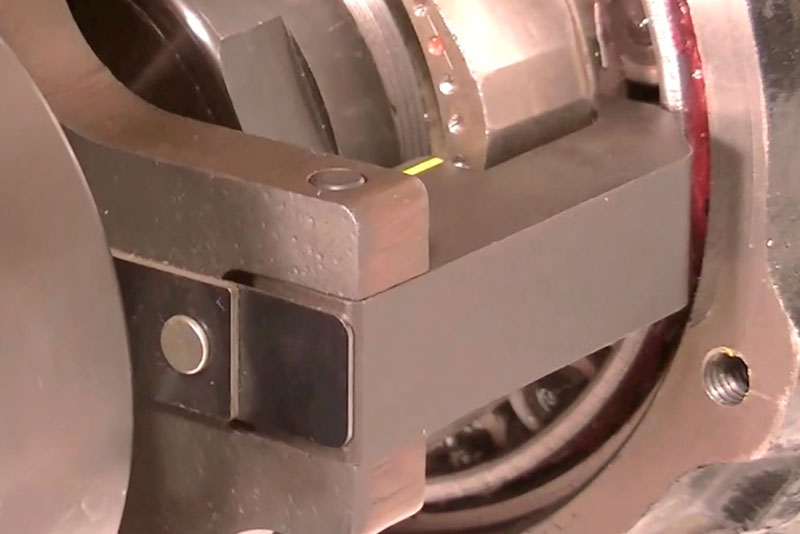

Mounting Doctor Preload

Seating the Bearing Rollers

Setting the Bearing

Locking Temper-Loc Nut

Removing Doctor Preload

Tips on Using the R Drive Axle Doctor Preload

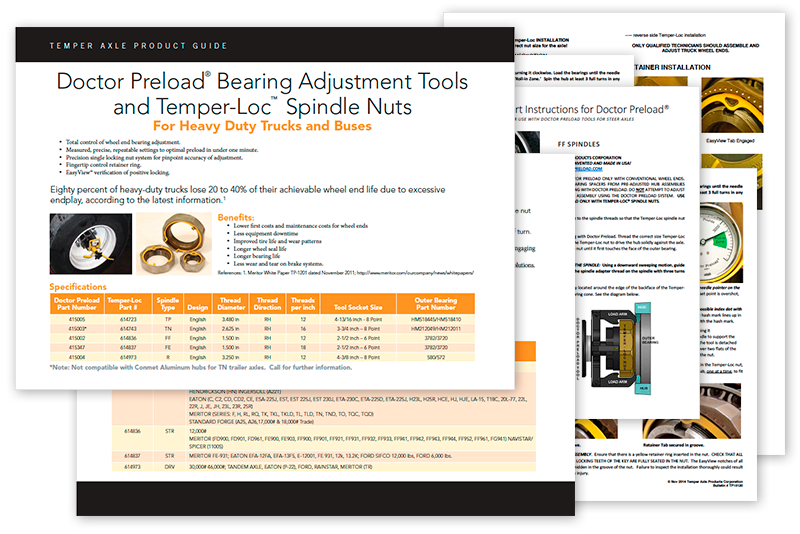

INSTRUCTIONS AND CATALOG SHEETS

-

Temper-Loc Nut Instructions

-

Temper Axle Product Catalog

-

900 Series Drive Axle Quick Start

-

Drive Axle Quick Start

-

Steer Axle Quick Start

-

900 Series Trailer Axle Quick Start TN

-

900 Series Trailer Axle Quick Start TP

-

Trailer Axle Quick Start: Quick Start TN-TP

-

Trailer Axle Quick Start: Quick Start TN-AH

Testimonials

FLEETS LOVE DOCTOR PRELOAD

Let’s Talk

WE’RE READY TO HELP YOU SAVE MONEY AND ANSWER YOUR QUESTIONS.

Call us today, (518) 853-3467, or feel free to fill out the form below and a member of our team will reach out to schedule a call with you.

Our Patents

Doctor Preload and/or its use may be covered by the following patents.

US 7,559,135

US 7,389,579

US 8,359,733

US 8,316,530

US 8,650,757

US 8,904,646

US 8,893,364

US 9,200,672

US 9,574,612

US 9,651,094

US 9,618,049

US 9,850,943

US 9,908,223

US 10,100,872

US 10,107,331

AU 2007200331

AU 2007234534

CA 2,576,337

GB 2434621B

IT 1379390

Temper-Loc and/or its use may be covered by the following patents.

US 7,303,367

US 7,625,164

US 8,961,090

US 9,200,672

US 9,200,673

US 9,217,461

US 9,651,094

AU 2006200842

AU 2011204889

AU 2008201252

CA 2,537,611

GB 2435499B

GB 2445501B

IT 1373751

SafetyCert and/or its use may be covered by the following patents.

US 9,217,461

US 9,217,561

US 9,587,667

US 9,909,609